Click on a question to reveal the answer below

About Water Softeners

The slippery feeling is due to the absence of the hardness minerals removed by the water softener and the natural feel of the oils in the skin.

Studies conducted at the University of Wisconsin- Madison, and the National Sanitation Foundation confirm that softener regeneration does not harm the bacteria in the septic system. In addition, NSF has shown several findings: The normal salt content found in unsoftened water is less than ideal for bacterial growth. The addition of sodium to the system was found to bring the bacterial environment closer to the optimal range. The volume of softener wastes are added to the septic tank slowly and are not of sufficient volume to cause any deleterious hydraulic load problems in septic tank systems. Water softener regeneration wastes not only should not interfere with septic tank system drain field soil percolation, but may actually improve soil percolation.

Drain to a laundry tub, standpipe or floor drain, providing an air gap for all installations. The drain field should be able to handle small amounts of brine regenerant.

Approximately two to five inches.

Yes, as long as it is protected from the elements, such as rain, freezing temperatures, and direct sunlight.

If electrical power to the softener goes off, the time display is blank, but the face plate timer keeps the correct time for 6 hours. When the electrical power comes on again, simply reset the present time only if the display is flashing. The hardness and recharge time never require resetting unless a change is desired.

No. In fact, depending on the model, there may be savings in salt and the total number of regeneration cycles in a larger unit. There could be a dependability benefit by reducing the total number of regenerations over the life of the softener with a larger grain capacity unit.

Troubleshooting Water Softeners

A salt bridge is hardened salt that has created an “arch” or “bridge” in the salt tank. It can be caused by filling the salt tank to the top with salt or excessively humid storage conditions. To remove the salt bridge, hold a broom handle, or like tool, up to the softener. Make a pencil mark on the handle, 1″ or 2″ below the top of the rim. Then carefully push it straight down into the salt. If a hard object is felt before the pencil mark gets to the top of the tank, it is most likely a salt bridge. Carefully push into the bridge in a few places to break it. Do not try to break the salt bridge by pounding on the outside of the salt tank, you may damage it. You may also use a small amount of warm water to soften if necessary.

There could be a number of reasons, such as:

- North Star units are very salt efficient and do not use much salt to regenerate.

- You possibly have a salt bridge.

- The nozzle and venturi could possibly be plugged.

There could be a number of reasons, such as:

- The unit is not sized properly

- The unit is not programmed correctly

- A leaky toilet or faucet is using up the softener’s capacity

- A salt bridge may be present in the tank

- Hot water is being used during regeneration time

- There is no salt in the unit

Possible increase in water hardness could be caused by:

- Hot water used when softener is regenerating: The water heater will refill with hard water.

- Leaking faucet or toilet valve: A small leak will waste hundreds of gallons of water in just a few days. Fix all water leaks immediately.

About Softener Salt

The amount of sodium added is dependent upon the hardness of the water being softened. For example, if the water hardness is 20 grains per gallon, the softener will add 150 milligrams of sodium to each quart of water. 150 milligrams of sodium is equal to eating one slice of white bread.

Use clean water softener salts only, at least 99.5% pure. Fill the tank with nugget or pellet water softener salt. Do not use rock, block, granulated ice cream salts, or salt with iron removing additives.They may contain dirt and sediments, or mush and cake, and may create maintenance problems. We recommend using Morton® System Saver® Pellets and/or Windsor® System Saver Pellets to maintain the efficiency of your North Star Water Softener.

Yes. Potassium chloride can be used in place of softener salt, however, you may have to set your softener to a higher hardness setting. As a result, more potassium chloride may have to be used than salt. In addition, potassium chloride may be more expensive than salt.

Water Softener Regeneration / Recharge

The electronic controller is programmed to know the water softener’s capacity. It uses the softener capacity, the hardness setting and the water usage from the meter to continuously adjust to the customer’s water using habits.

The electronic controller is searching for a water usage pattern and may seem to regenerate more frequently or not enough for the first few weeks of installation.

It will discharge approximately 40 gallons to the drain during a recharge. Visit the Flow Rate Page or consult your Manual for flow rates.

The regeneration cycle will take approximately 2 hours but may take longer depending on the settings. It is factory set to recharge at 2:00AM as this is a good time in most households because water is not in use. The default setting allows the timer to control regeneration frequency based on water usage readings from the water meter. It provides the most economical operation.

It will use .9 pounds of salt per minute of fill time. Depending on your water usage, the water softener will use between 2-1/2 and 7 lbs. salt per regeneration.

Water Softener Warranties

For a period of ten years from date of purchase, the fiberglass mineral tank will not rust, corrode, leak, burst or in any other manner fail to perform their proper function. For a period of five years from date of purchase, the salt storage tank will not rust, corrode, leak, burst or in any other manner fail to perform their proper function. For a period of 1 year after installation, the valve and electronic control board will be free of defects in material and workmanship and will perform their proper functions. For a period of one year from date of purchase, the complete unit will not fail to perform its proper function.

General Water Softener Maintenance

Brine (salt dissolved in water) is needed for each and every regeneration. The water for making brine is metered into the salt storage area by the softener valve and timer. However, you must keep the tank full of salt. NOTE: In humid areas, it is best to fill with less salt, more often.

Check the salt level a few weeks after you install the softener and every week after that. Add when the brine tank is from 1/3 to 1/2 full. Never allow the softener to use all the salt before you add more. Without salt, you will soon have hard water. Use clean water softener salts only, at least 99.5% pure. NUGGET, PELLET or coarse SOLAR salts are recommended. Do not use rock, block, granulated, and ice cream making salts. They contain dirt and sediments, or mush and cake, and will create maintenance problems. For best results, North Star recommends Morton® System Saver® Pellets and/or Windsor® System Saver for use in this water softener.

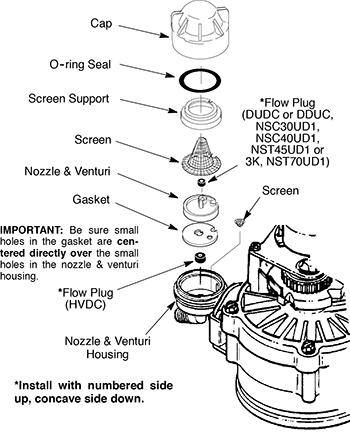

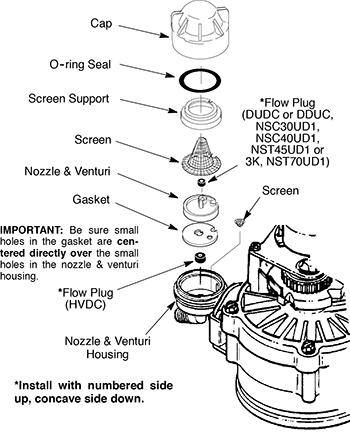

Your water softener takes hardness minerals (calcium and magnesium) out of the water. Also, it can control some clear water iron. With clear water iron, water from a faucet is clear when first put into a glass. After 15 to 30 minutes, the water begins to cloud or turn rust colored. A water softener WILL NOT remove any iron that makes the water cloudy or rusty as it comes from the faucet (called red water iron). To take red water iron out of water, or over the maximum of clear water iron, an iron filter or other equipment is needed. Your local dealer has trained people to help you with iron water problems. If your water supply has clear water iron, periodic resin bed cleaning is needed. Clean the bed at least every six months, or more often if iron appears in the soft water between treatments. Follow directions on the resin bed cleaner container. Cleaning the nozzle and venturi: A clean nozzle and venturi is needed for the softener to work right. This small unit makes the suction to move brine from the salt storage area to the resin tank during regeneration. If it becomes plugged with sand, silt, dirt, etc., the softener will not work and you will get hard water. To get to the nozzle and venturi, remove the softener top cover. Be sure the softener is in service cycle (no water pressure at nozzle and venturi). Then, while holding the nozzle & venturi housing with one hand, turn off the cap. Lift out the screen support and screen, then the nozzle and venturi. Wash and rinse the parts in warm water until clean. If needed, use a small brush to remove iron or dirt. Also check and clean the gasket. NOTE: Some models have a small flow plug located in the nozzle and venturi, and/or a small cone shaped screen in the housing. Be sure to check and clean these parts, if your model is so equipped. Carefully replace all parts in the correct order. Lubricate the o-ring seal with silicone grease and place in position. Install and tighten the cap, BY HAND ONLY. DO NOT OVER TIGHTEN, WHICH MAY BREAK THE CAP OR HOUSING.